GENERAL

Roof Brackets: Silent Support

Roof Brackets: The Hidden Backbone of Support

Roof Brackets: Silent Support

Roof brackets may be small, but they play a powerful role in construction. These hidden heroes provide the strength and stability that keep roofs secure, especially during repairs or installations. Without them, working safely at heights would be nearly impossible.

The role of roof bracket is huge. They spread the roof’s weight evenly. This keeps the building stable and safe. Knowing how roof bracket work helps us see how important a good roof support system is.

Key Takeaways

- Roof bracket are essential for the structural integrity of roofs.

- They help distribute the weight of the roof evenly.

- A well-designed roof support system is critical for building safety.

- Understanding roof bracket helps us appreciate the complexity of roof support systems.

- Proper roof support is vital for a building’s long life.

The Essential Role of Roof Brackets in Structural Integrity

Roof bracket are key to keeping roofing systems stable. They offer support to the roof, helping it handle environmental stresses.

What Are Roof Brackets and How Do They Function?

Roof bracket are tools attached to the roof for extra support. They help spread the weight of the roof, preventing damage or collapse. Properly installed roof bracket protect workers and extend the roof’s life. Experts say a well-supported roof is vital for a safe, lasting building.

Historical Development of Roof Support Systems

Roof support systems have changed a lot over time. Early roofs used simple wooden supports. Now, thanks to new materials and tech, roof bracket are stronger and last longer. Modern brackets, made from steel and aluminum, offer better strength.

Why Proper Bracket Support Is Non-Negotiable

Without enough roof bracket support, roofs can collapse, hurting workers. The strength of a building depends on its weakest part, and roof bracket are critical. Making sure roof bracket are installed and kept up is essential for safety and roof longevity.

Types of Roof Brackets for Different Applications

The type of roof bracket used is key to a roofing project’s success. Roof bracket are made for different needs, ensuring each project gets the right support.

Adjustable Roof Brackets for Varied Pitches

Adjustable roof bracket are perfect for roofs with changing or non-standard pitches. They can adjust to fit various angles, making them flexible and versatile. They’re great for renovation projects where the roof isn’t uniform.

Fixed Roof Brackets for Standardized Projects

Fixed roof bracket are for projects with standard roof pitches. They provide strong support for roofing materials during installation. These brackets are best for new construction projects with consistent roof designs.

Specialty and Custom Roof Brackets

Specialty and custom roof bracket are for unique or complex projects. They’re made to fit specific needs, like unusual roof shapes or heavy materials. They’re the answer for projects that standard brackets can’t handle.

Temporary vs. Permanent Installation Options

Roof bracket can be set up temporarily or permanently, based on the project’s needs. Temporary setups are common in construction or repair, providing a safe area to work. Permanent setups become part of the roof, giving long-term support.

Quick-Release Systems

Quick-release systems are for temporary setups, making it easy to remove the brackets after the work is done. This is handy in construction where speed and efficiency matter.

Permanent Anchoring Methods

Permanent anchoring methods secure the brackets to the roof, making them a permanent part of it. This ensures long-term stability and support for the roofing materials.

| Type of Roof Bracket | Application | Installation Type |

| Adjustable | Varied roof pitches | Temporary or Permanent |

| Fixed | Standardized roof pitches | Permanent |

| Specialty/Custom | Unique or complex roofs | Temporary or Permanent |

Materials and Construction of Quality Roof Brackets

The durability and effectiveness of roof bracket depend on the materials used. Quality roof bracket can handle different weather conditions and heavy loads. Choosing the right material is key.

Steel and Metal Alloy Options

Steel and metal alloys are top choices for roof bracket They are strong and last long. Galvanized steel or other coatings help them last even longer.

Aluminum and Lightweight Alternatives

Aluminum and other light materials are good for when weight matters. They are strong but light, perfect for homes or easy installations.

Weather Resistance and Protective Coatings

Weather resistance is key for roof bracket to last. Coatings like galvanization or anodizing protect them from corrosion. The right coating depends on the weather.

Load-Bearing Capacity and Structural Design

The strength of roof bracket comes from their design and materials. A good bracket is strong but also uses materials wisely. The table below shows how different materials compare.

| Material | Load-Bearing Capacity (kg) | Durability |

| Steel | 500-1000 | High |

| Aluminum | 200-500 | Medium |

| Galvanized Steel | 500-1000 | Very High |

In conclusion, the materials and design of roof bracket are very important. The right choice ensures safety and durability in roofing projects.

Comprehensive Roof Bracket Installation Guide

Installing roof bracket is a detailed task that needs careful attention and safety standards. It’s important for the roof’s strength and long life.

Pre-Installation Assessment and Planning

First, check the roof’s structure well. Look at its condition, material, and slope to pick the right bracket. Planning is key for a good install, as it spots problems and picks the right tools.

Tools and Equipment Required

Right tools and equipment are key for a smooth install. You’ll need drills, wrenches, measuring tapes, and safety gear. The quality of the tools affects the install’s success and worker safety.

Step-by-Step Installation Process

The install process has several important steps:

Marking and Measuring

Marking and measuring accurately is vital. Measure the roof’s size and mark where to put the brackets.

Securing to Roof Structure

After marking, secure the brackets to the roof. Use the right fasteners and make sure they’re tight for all weather.

Testing for Stability

Test the brackets for stability after installing. Apply a load and check for weakness or instability.

Common Installation Pitfalls and Solutions

Even with planning, problems can happen. Common issues are wrong measurements, poor securing, and wrong bracket types. Solutions include double-checking measurements, following manufacturer guidelines, and getting help when needed.

- Ensure accurate measurements to avoid misalignment.

- Use the correct type of bracket for the roofing material and pitch.

- Regularly inspect the installation process to catch and rectify any issues early.

Safety Standards and Compliance for Roof Brackets

Roof bracket must meet safety standards to ensure the safety and quality of roofing work. They must support loads and protect workers from falls. This is why they are regulated.

OSHA Requirements and Industry Regulations

The Occupational Safety and Health Administration (OSHA) has rules for roof bracket These cover load capacity, material strength, and how to install them. Following these rules is key to avoiding accidents and keeping workers safe.

Industry rules also shape roof bracket safety standards. Following these rules helps ensure legal compliance and improves roofing project safety and quality.

Load Capacity Ratings Explained

Knowing about load capacity ratings is important for roof bracket safety. These ratings show the maximum weight a bracket can handle. This includes the weight of workers, tools, and materials. It’s important to pick brackets that match the project’s needs.

Fall Protection Integration with Bracket Systems

Fall protection is a big part of roofing safety, and roof bracket are key. They help integrate fall protection systems to keep workers safe from falls. This includes:

Guardrail Compatibility

Guardrails are a common safety feature that work with roof bracket. It’s important that roof bracket fit with guardrails to ensure a safe work area.

Personal Fall Arrest System Anchoring

Personal Fall Arrest Systems (PFAS) are also vital for fall protection. Roof bracket can be anchor points for PFAS, as long as they are strong and stable enough.

By following these safety steps, the risk of falls can be greatly lowered. This makes the workplace safer for everyone.

Roof Brackets for Residential vs. Commercial Applications

Roof brackets for homes and businesses are very different. They need to be strong and fit the project’s needs. Home roof bracket are lighter and simpler, while business ones are stronger and more complex.

Residential Roofing Support Requirements

Home roofs use lighter materials and simpler designs. Roof bracket for homes support roofs with materials like asphalt shingles or metal. They are made for easy installation, perfect for DIY projects or small teams.

Commercial and Industrial-Grade Bracket Systems

Business roofs need stronger brackets to handle more weight and bigger spans. These brackets can handle high winds and heavy materials. They need special installation and follow strict building codes.

Compatibility with Different Roof Types

Roof bracket must work with many roof types, like asphalt, metal, and tile. They must support the roof without harming it.

Asphalt Shingle Roofs

Roof bracket for asphalt shingle roofs are light and easy to put up. They attach to rafters or trusses without damaging the shingles.

Metal Roofing Systems

Metal roofs need brackets that hold the panels securely. These brackets have special clamps to prevent leaks or damage.

Tile and Specialty Roofing

Tile roofs, like slate or clay, need brackets that fit their shape and weight. These brackets spread the load evenly to avoid tile damage.

Maintenance, Inspection, and Longevity of Roof Brackets

To keep roofing systems stable, roof bracket upkeep is key. Regular checks and maintenance are vital. They help keep roofs strong and lasting.

Regular Inspection Protocols and Checklists

Regular checks are important to spot problems early. A detailed checklist should cover bracket alignment, wear signs, and secure connections.

- Inspect bracket alignment and adjust as necessary

- Check for corrosion or damage

- Verify secure connections

Weathering Effects and Preventative Maintenance

Weather can harm roof bracket To fight this, use protective coatings and ensure good drainage. These steps help protect against weather damage.

“Regular maintenance is key to extending the life of roof bracket. By protecting against corrosion and wear, we can ensure the structural integrity of the roofing system.” – Industry Expert

Signs of Wear and When to Replace

Spotting wear signs is important for knowing when to replace brackets. Look for rust, corrosion, and deformation.

| Signs of Wear | Action Required |

| Rust or Corrosion | Replace bracket |

| Deformation | Replace bracket |

| Loose Connections | Tighten or replace fasteners |

Storage Best Practices for Temporary Brackets

Storing temporary roof bracket right is critical. Keep them in a dry, safe spot, away from the weather.

By sticking to these tips and being proactive, inspectors and contractors can keep roofs safe and lasting.

Selecting the Right Roof Brackets for Your Specific Project

The right roof bracket are key to a successful roofing project. They provide the support and stability needed. It’s important to pick roof bracket that fit your project’s needs.

Assessing Project Requirements and Constraints

To find the right roof bracket first look at your project’s needs. Think about the roofing material, roof pitch, and load-bearing capacity. Knowing these will help you choose the best brackets for your project.

Cost vs. Quality: Making Informed Decisions

Choosing roof bracket means balancing cost and quality. It’s tempting to go for the cheapest, but think about the long-term. Quality brackets last longer and need less upkeep, saving you money and avoiding accidents.

| Factor | Low-Cost Brackets | High-Quality Brackets |

| Material | Thin, lightweight metal | Thick, durable metal alloys |

| Load-Bearing Capacity | Lower capacity | Higher capacity |

| Maintenance | Frequent maintenance required | Less maintenance required |

Professional Recommendations and Industry Best Practices

For the best choice, get professional advice and follow industry standards. Talking to experienced contractors can guide you to the right roof brackets. Also, keeping up with the latest standards ensures you make smart choices.

Conclusion: Investing in Quality Roof Support for Long-Term Safety and Stability

Investing in quality roof bracket is key for the long-term safety and stability of roofs. Throughout this article, we’ve seen how important roof bracket are. They help support roofs and handle different weather conditions.

It’s vital to pick the right roof bracket for your project. You need to think about the material, design, and how much weight they can hold. This ensures they can handle the roof’s weight and any extra loads.

By focusing on quality roof support, you can avoid accidents and save on maintenance costs. You can also make your roof last longer. Always talk to experts and follow the best practices for choosing and installing roof bracket. This way, you ensure your roof stays safe and stable for a long time.

FAQ

What is the primary function of roof brackets in roofing systems?

How do I choose the right type of roof bracket for my roofing project?

What materials are commonly used to manufacture roof brackets?

How do I ensure that my roof brackets are installed correctly?

What safety standards should roof brackets comply with?

Can roof bracket be used for both residential and commercial roofing applications?

How often should roof bracket be inspected and maintained?

What factors should be considered when selecting roof bracket for a specific project?

Are there different roof bracket options for various roof types, such as asphalt shingle, metal, and tile roofing?

GENERAL

Why Anon Vailt Is a Top Privacy-Focused Vault

Anon Vailt is an innovative platform designed for anonymous cloud storage and secure file backups. Unlike traditional cloud services, it emphasizes zero-knowledge storage, meaning the provider doesn’t have access to your encryption keys or data content. This approach ensures data privacy protection for individuals, freelancers, and businesses handling sensitive documents.

At its core, Anon Vailt positions itself as more than just a file repository. It’s a secure online vault that combines strong encryption, user-friendly design, and features tailored to 2025’s security standards.

Key Features of Anon Vailt

When evaluating any cloud platform, understanding its features is critical. Here’s what users can expect from anon vailt app features:

Encrypted File Vault

All files are encrypted before leaving your device, ensuring that no third party—including the platform—can access your content. This level of protection is crucial for personal documents, legal files, and sensitive work materials.

Secure File Storage

With secure file storage, users can upload, organize, and manage files with confidence. Multi-layer authentication and robust encryption standards are built into the platform.

Zero-Knowledge Storage

Anon Vailt uses a zero-knowledge storage model, meaning even if the servers were compromised, your files remain unreadable without your private keys.

Cyber Security Storage Tools

Advanced tools monitor file integrity, detect suspicious login attempts, and alert users to potential threats. For those who prioritize cyber security storage tools, this is a notable advantage over conventional cloud providers.

Anonymous Cloud Storage Access

You can access your files without linking personal identifiers, allowing for anonymous cloud storage experiences that protect your digital footprint.

How to Use Anon Vailt

Using the platform is straightforward, yet robust:

Anon Vailt Login – Sign up using a unique username and strong password. No personal email is required.

File Upload – Drag and drop files into the secure online vault. All files are automatically encrypted.

Organization – Categorize files, set permissions, or create folders.

Sharing – If needed, generate secure links without exposing your identity.

Backup – Use secure file backup features to ensure redundancy.

It’s a mix of convenience and security — ideal for both personal use and professional environments where privacy is non-negotiable.

Anon Vailt Review: Pros and Cons

A detailed anon vailt review must balance usability with risk awareness.

Pros

- Strong encryption and data privacy protection

- Anonymous account creation and access

- Easy-to-use interface with intuitive anon vailt app features

- Encrypted storage solutions compatible across devices

- Safe secure file backup options for critical documents

Cons

- Free tier may have limited storage

- Advanced features require subscription

- No native collaboration tools for teams (as of 2025)

A user comment from a privacy forum highlights the value:

“Anon Vailt gave me peace of mind — my sensitive documents feel safer here than anywhere else.”

Why Anon Vailt is a Leading Privacy-Focused Cloud Vault

The platform’s popularity stems from its combination of cloud privacy software and modern security protocols:

- AES-256 encryption on all files

- Optional two-factor authentication for anon vailt login

- No metadata retention

- Cross-platform access: desktop, mobile, and web

Users seeking the safest way to store personal or professional files often rank Anon Vailt above conventional cloud platforms for encrypted file vault needs.

Security Practices for Anon Vailt Users

Even with a secure platform, best practices matter:

- Strong, unique passwords – Avoid reusing credentials

- Two-factor authentication – Adds an extra layer of security

- Regular updates – Keep your devices secure

- Cautious sharing – Only share links with trusted parties

Implementing these practices maximizes the benefits of secure online vaults.

Comparing Anon Vailt to Other Cloud Storage Options

While traditional services like Google Drive and Dropbox are convenient, they often lack:

- True anonymity

- End-to-end encryption by default

- Zero-knowledge storage

It fills this gap, making it a privacy-focused cloud vault choice for anyone serious about data privacy protection.

Anon Vailt App Features in 2025

The latest iteration of the app emphasizes usability:

- File preview without download

- Drag-and-drop folder organization

- Mobile push notifications for file activity

- Encrypted offline storage for on-the-go access

- Seamless secure file backup integration

This ensures users don’t sacrifice convenience for security.

Best Practices for Safe Usage

Even with strong encrypted storage solutions, user behavior is critical:

Avoid logging in from public networks

Regularly update your cloud privacy software

Monitor activity logs

Keep personal identifiers separate from account info

Following these steps ensures the encrypted file vault remains truly secure.

Real-Life User Example

One cybersecurity enthusiast shared:

“I moved all my client files to Anon Vailt last year. Between the zero-knowledge encryption and anonymous login, I feel confident sharing sensitive info.”

This reflects the growing trend toward privacy-first cloud solutions.

FAQ’s

Is Anon Vailt really anonymous?

Yes, the platform allows account creation without personal identifiers, maintaining privacy for users who prefer anonymity.

How secure is Anon Vailt for sensitive files?

With AES-256 encryption and zero-knowledge storage, your files are highly secure even if servers are compromised.

Can I use Anon Vailt for business documents?

Absolutely. While collaboration tools are limited, the platform is ideal for storing confidential business documents safely.

Are there alternatives to Anon Vailt?

Yes, other privacy-focused cloud vaults and encrypted storage solutions exist, but few combine usability with strong anonymity like Anon Vailt.

Conclusion

Anon Vailt is more than just a cloud storage service — it’s a secure, anonymous, and privacy-focused vault designed for today’s digital challenges. For individuals and professionals prioritizing confidentiality, it offers unmatched peace of mind.

GENERAL

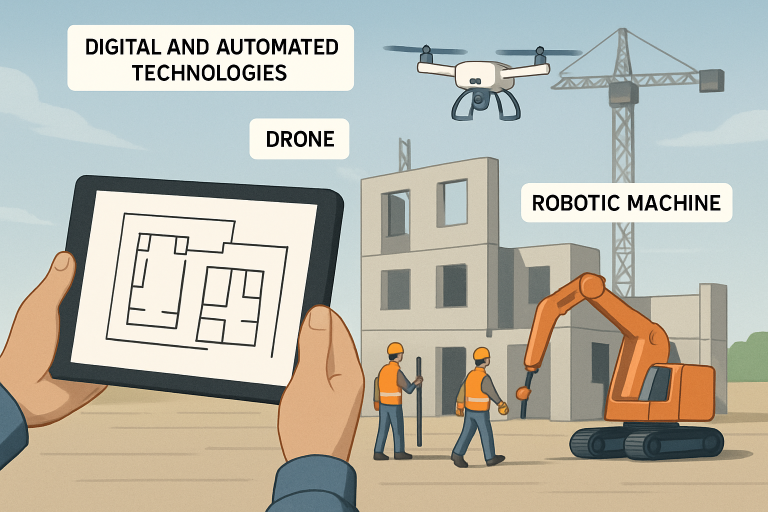

How Modern Construction Techniques Are Changing the Way We Build

As the construction industry ushers in a new era, breakthrough techniques and technologies are transforming both residential and commercial projects. The result is a built environment that is more efficient, adaptable, and eco-friendly than ever before. Homeowners and developers eager to capitalize on these advancements can work with trusted Fort Mill remodelers who blend local expertise with state-of-the-art methods to deliver stunning, future-ready spaces. Modern construction practices prioritize performance, longevity, and sustainability, moving beyond traditional building methods. Both the residential and commercial sectors are embracing interconnected data, advanced machinery, and intelligent materials to optimize results and minimize environmental impact. Innovations like modular construction and adaptive reuse not only reduce costs but also transform urban landscapes. These trends reflect the industry’s evolution in response to the needs of contemporary living and its ability to adapt to changing demands.

Building Information Modeling (BIM) Enhancements

Building Information Modeling has evolved from a simple drafting tool into a sophisticated data-centric platform. The latest systems, often referred to as 5D BIM, combine detailed design with cost analysis, scheduling, and real-time construction updates. This holistic approach enables project managers to generate “digital twins”—highly detailed virtual replicas of buildings that allow for instant conflict detection and performance optimization. Home builders and commercial developers benefit from enhanced coordination and fewer surprises on the jobsite, driving efficiency even on complex, multi-phase projects.

Drones and Augmented Reality (AR) Integration

Surveying and site inspections are rapidly moving into the digital age through the adoption of drones equipped with AI and advanced sensors. These airborne tools provide 3D site scans that are incredibly fast and accurate, improving documentation and streamlining regulatory compliance. Augmented Reality tools then overlay project models onto real-world environments, enabling seamless collaboration among architects, builders, and clients and minimizing the risk of design flaws or costly revisions during construction.

Robotics and Automation in Construction

Automation and robotics have shifted from factory conveyor belts directly to the construction site. Today’s robots can perform repetitive, high-precision jobs such as masonry, rebar tying, and onsite fabrication. This not only enhances safety—by reducing human exposure to hazardous environments—but also delivers consistently high-quality work while accelerating project timelines. Automated processes for cutting and preparing building materials directly from digital plans are further reducing waste and keeping projects on schedule.

Generative AI for Design and Planning

Generative AI in construction is enabling professionals to refine designs and ensure code compliance with unprecedented efficiency. By automating complex calculations and layout creation, these tools empower teams to explore a vast array of design options, identifying the optimal use of space and resources for both homes and commercial developments. As accessibility improves, generative AI is expected to become standard practice, especially for urban infill and high-performance buildings where precision is paramount.

Sustainable Materials and Systems

Eco-friendly construction is no longer an exception—it’s quickly becoming the rule. Smart materials such as self-healing concrete actively extend the lifespan of structures. At the same time, low-emission paints and energy-generating solar panels contribute to health and cost savings in residential settings. In the commercial sphere, advanced IoT-based energy management systems monitor usage, drastically reducing unnecessary consumption and cutting operational incidents by more than 50%.

Modular and Prefabricated Construction

Off-site construction is rewriting the rules, offering a sustainable, highly controlled building process. Prefabricated modules are custom-built in workshops before being assembled at the construction site. This method accelerates timelines, ensures tighter quality control, and minimizes the logistics challenges and community disruptions often associated with traditional builds. Additionally, modular construction is driving affordability and diversity in housing and commercial solutions.

Adaptive Reuse and Mixed-Use Developments

Adaptive reuse represents a powerful form of urban renewal, transforming obsolete or historic structures into vibrant spaces for modern living, retail, or culture. Such projects extend the lifespan of buildings with significant cultural value while reducing demolition waste and preserving their architectural character. Similarly, emerging mixed-use developments combine residential, commercial, and community amenities in walkable, human-centered districts that promote economic vitality and social connection.

Conclusion

The construction sector is experiencing an era of remarkable innovation, driven by digital advancements, intelligent automation, and sustainable practices. By leveraging these techniques, builders and property owners are not simply keeping pace with contemporary needs—they are creating adaptable and enduring spaces that set new standards for the industry’s future.

GENERAL

Top Drain Cleaner Toronto Services You Can Trust

A professional drain cleaner Toronto uses advanced tools such as drain snakes, high-pressure jetters, and camera inspection systems to identify and eliminate the root cause of the problem. Whether it’s grease buildup, tree roots, or foreign debris, trained technicians don’t just treat the symptom — they fix the source.

Understanding Drain Cleaning Toronto Services

The Basics of Sewer & Drain Cleaning Toronto ON

Toronto’s plumbing infrastructure connects thousands of homes and businesses to a vast municipal sewer system. Over time, grease, dirt, and sediment accumulate, restricting water flow. Sewer & drain cleaning Toronto ON professionals use specialized equipment to clear these obstructions without damaging your pipes.

Typical services include:

- Main line cleaning to remove buildup in the primary sewer connection.

- Kitchen and bathroom drain unclogging to clear hair, grease, and food particles.

- Storm drain cleaning to prevent flooding during heavy rainfall.

- Preventive maintenance programs for long-term performance.

Signs You Need a Clogged Drain Toronto Plumber

Sometimes a clog develops slowly, giving you subtle warnings before a full backup occurs. If you notice any of these signs, it’s time to call a clogged drain Toronto plumber:

- Gurgling sounds when using sinks or tubs.

- Water pooling around drains or toilets.

- Unpleasant odors coming from pipes.

- Slow-draining sinks or bathtubs.

- Backflow from toilets or floor drains.

These symptoms often indicate a developing blockage in your drain or main sewer line that requires immediate professional attention.

Hydro-Jetting Drain Cleaning Toronto: The 2025 Standard

For stubborn or recurring blockages, hydro-jetting drain cleaning Toronto has become the gold standard. This eco-friendly method uses high-pressure water jets (up to 4,000 PSI) to blast through grease, roots, and mineral buildup. It’s powerful enough to clean the inside of pipes thoroughly, leaving them almost like new.

Benefits of hydro-jetting include:

- Non-invasive and chemical-free.

- Ideal for both residential and commercial drains.

- Effective against grease, sludge, and root intrusion.

- Prevents future clogs with deep cleaning.

Toronto homeowners love hydro-jetting because it’s both safe and sustainable — no harsh chemicals, just water pressure doing the hard work.

When You Need an Emergency Drain Cleaner Toronto GTA

Clogs don’t care about your schedule. Late-night backups, overflowing toilets, or basement floods require immediate response. That’s where an emergency drain cleaner Toronto GTA comes in.

Emergency technicians are available 24/7 to handle crises such as:

- Sewer backups during storms.

- Overflowing drains in multi-unit buildings.

- Burst or frozen drain lines in winter.

A homeowner once shared, “I woke up to water in my basement at 2 AM, but a local Toronto drain cleaner arrived within 30 minutes. They cleared a tree root blockage before it got worse — absolute lifesaver!”

That’s the kind of reliability that separates professionals from amateurs.

Kitchen Drain Unclog Toronto: The Heart of Home Maintenance

Kitchens are often the most common source of plumbing issues. Grease, food particles, and soap residue can easily cause buildup inside pipes. A professional kitchen drain unclog Toronto service uses mechanical snakes or hydro-jetting to safely break down the clog without harming your plumbing.

Pro tip: To prevent kitchen clogs, avoid pouring grease or coffee grounds down the sink. Installing a mesh strainer also helps trap debris before it enters your pipes.

Main Sewer Line Cleaning Toronto: Protecting Your Foundation

Your main sewer line connects all household drains to the city’s sewer system. If this line gets clogged, it can cause backups in every drain in your home. Main sewer line cleaning Toronto services are crucial for older neighborhoods like East York, The Junction, and Leslieville, where tree roots often invade underground pipes.

Professionals use drain cameras to inspect blockages and hydro-jetting or mechanical cutters to clear them effectively. Early detection prevents expensive foundation or landscaping damage.

Toronto Drain Snake Service: Simple Yet Effective

A Toronto drain snake service remains one of the most affordable and effective ways to tackle minor blockages. Using a flexible auger, technicians manually remove obstructions in sinks, showers, and small drains. It’s the go-to method for localized issues like hair clogs or soap buildup.

While it’s a simple fix, it’s best handled by trained experts to avoid pipe damage, especially in older Toronto homes with delicate plumbing.

Why Hire a Licensed Drain Technician Toronto

Hiring a licensed drain technician Toronto ensures you’re working with certified professionals who follow plumbing codes and safety regulations. Licensed experts diagnose problems accurately using advanced tools like drain camera inspection Toronto systems and provide lasting solutions — not temporary fixes.

Their expertise reduces the risk of pipe damage, ensures warranty compliance, and improves overall system efficiency.

Affordable Drain Cleaner Toronto: Quality Without Compromise

Affordability doesn’t have to mean cutting corners. Several affordable drain cleaner Toronto services offer transparent pricing, free estimates, and no hidden fees. When comparing providers, look for those who:

- Offer upfront quotes.

- Use modern equipment (like hydro-jetting).

- Have verified Google reviews.

- Provide warranties on services.

You can get excellent results without overspending — it’s all about choosing the right company.

Residential Drain Cleaning Toronto: Home Comfort Restored

For homeowners, residential drain cleaning Toronto focuses on everyday plumbing issues — kitchen sinks, showers, bathtubs, and toilets. Regular cleaning prevents costly emergencies and keeps water flowing freely.

Scheduling professional drain maintenance once or twice a year helps you avoid unpleasant surprises, especially in older Toronto neighborhoods where pipes tend to corrode faster.

Commercial Drain Cleaning Toronto: For Businesses That Can’t Stop

Restaurants, hotels, and retail outlets rely heavily on functional plumbing. A single clog can disrupt operations, cause odors, and even lead to health code violations. Commercial drain cleaning Toronto providers offer maintenance plans, after-hours service, and high-capacity equipment to minimize downtime.

Hydro-jetting is particularly effective for commercial kitchens where grease and food waste accumulate quickly. Regular maintenance means smooth operations and satisfied customers.

Drain Camera Inspection Toronto: See the Problem Clearly

One of the most valuable tools in modern plumbing is the drain camera inspection Toronto system. This technology involves sending a small waterproof camera through your pipes to identify blockages, cracks, or leaks.

Benefits include:

- Accurate diagnosis without guesswork.

- Clear video footage of pipe conditions.

- Prevention of unnecessary excavation.

- Better maintenance planning.

It’s a proactive way to manage plumbing systems in both homes and businesses.

Root Intrusion Drain Cleaning Toronto

Toronto’s tree-lined neighborhoods are charming, but roots can wreak havoc underground. Tree roots often penetrate small cracks in pipes searching for moisture. Over time, they expand, causing severe blockages or pipe breaks.

Root intrusion drain cleaning Toronto services use mechanical cutters and hydro-jetting to remove roots safely and restore flow. Preventive maintenance is key — catching the issue early saves thousands in potential repair costs.

Toronto Plumber Drain Cleaning Cost

The cost of Toronto plumber drain cleaning varies based on the severity of the clog and the service type. On average:

- Basic drain snaking: $150–$250

- Hydro-jetting service: $300–$600

- Drain camera inspection: $150–$300

- Main sewer line cleaning: $400–$900

Factors like property size, pipe material, and accessibility may influence final pricing. Always ask for an estimate upfront to avoid surprises.

Real-Life Example: A Toronto Home Saved by Timely Cleaning

In 2024, a North York family noticed recurring water backups in their basement. They called a licensed drain technician Toronto, who discovered root intrusion using a camera inspection. A quick hydro-jetting session cleared the issue — saving them from a $7,000 sewer line replacement.

That’s the power of proactive maintenance.

FAQ’s

How often should I get my drains cleaned in Toronto?

For most homes, professional cleaning every 12–18 months prevents buildup and keeps drains flowing freely.

Are chemical drain cleaners safe for old Toronto homes?

No. Chemical cleaners can corrode older metal or clay pipes. Opt for professional methods like snaking or hydro-jetting instead.

What’s the fastest way to fix a clogged kitchen drain in Toronto?

Calling a kitchen drain unclog Toronto expert is safest. They’ll identify the exact cause and use mechanical tools or hydro-jetting for a permanent fix.

How do I choose the right drain cleaner Toronto service?

Look for licensed, insured professionals with strong customer reviews and transparent pricing. Avoid services that rely solely on chemical treatments.

Final Thoughts

Finding the right drain cleaner Toronto service can mean the difference between a quick fix and a costly disaster. From residential drain cleaning Toronto to commercial drain cleaning Toronto, and even emergency drain cleaner Toronto GTA options, Toronto homeowners now have access to advanced, eco-friendly, and reliable plumbing solutions.

-

HEALTH8 months ago

HEALTH8 months agoPure Clarity: The Power of Saline Contact Solution

-

GENERAL10 months ago

GENERAL10 months agoUnveiling the 322 Messianic Prophecies: A Deep Dive

-

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoWhat happened to spank bang

-

FASHION10 months ago

FASHION10 months agoDebonair blog:The Art of Stylish Living

-

ENTERTAINMENT10 months ago

ENTERTAINMENT10 months agoWhat Is JerkMate? Exploring the Features and Purpose

-

FASHION10 months ago

FASHION10 months agoUnderstanding the Carmelita Neck: A Unique Fashion Detail

-

ENTERTAINMENT10 months ago

ENTERTAINMENT10 months agoDrake Exposed: The Untold Truth Behind the Music and Fame

-

BUSINESS10 months ago

BUSINESS10 months agoCrypto FintechZoom: Navigating the Future of Digital Finance