TECHNOLOGY

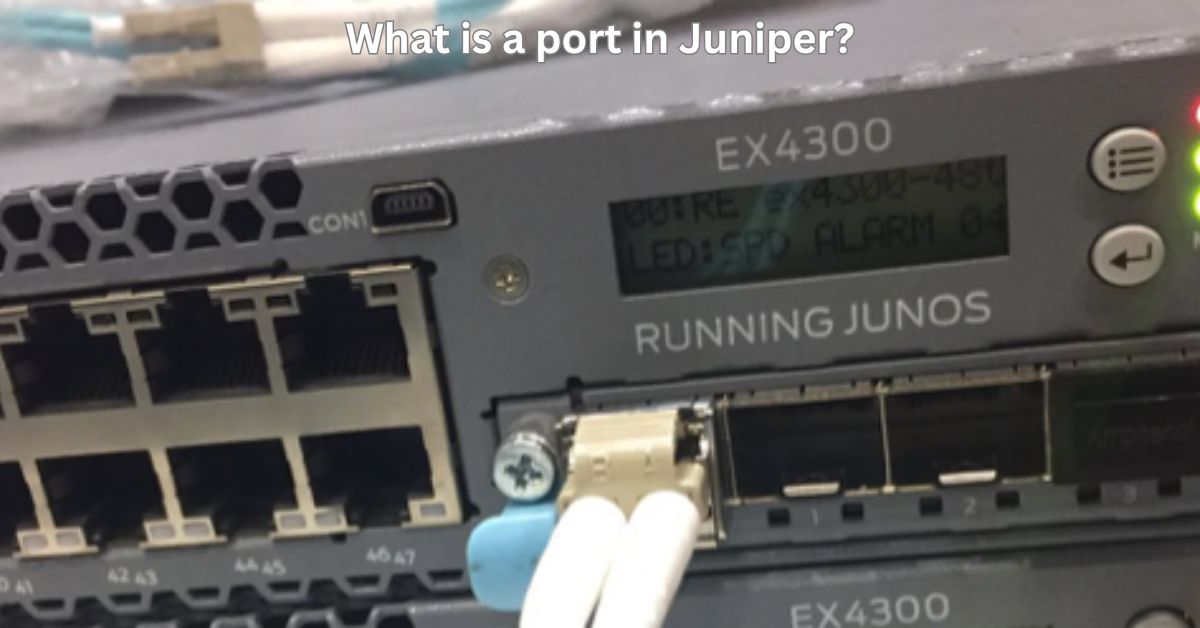

Understanding Port in Juniper: A Key to Network Connectivity

TECHNOLOGY

Mastering Mobile App Developing: A Complete Guide

TECHNOLOGY

Kingxomiz: The Rise of a Digital Empire

Kingxomiz: The Rise of a Digital Empire

In the ever-evolving digital landscape, a new name has emerged that’s captivating the attention of industry experts, investors, and technology enthusiasts alike. Kingxomiz is fast becoming a force to be reckoned with, showing immense potential to redefine how digital businesses operate, grow, and expand in today’s world. With its innovative approach and forward-thinking strategies, Kingxomiz is not just a company—it’s shaping up to be a digital empire.

This article delves into the origins, growth, and impact of Kingxomiz, exploring the factors behind its rise and the significance it holds in the digital world.

What is Kingxomiz?

Before delving into the reasons behind the rapid rise of Kingxomiz, it’s important to understand what the company represents. Kingxomiz is a cutting-edge digital platform that combines various aspects of technology, business, and digital transformation to create innovative solutions for industries ranging from e-commerce and fintech to entertainment and software development.

Kingxomiz’s approach is multifaceted, focusing on delivering high-quality products and services that empower businesses to thrive in a competitive, ever-changing digital ecosystem. By leveraging artificial intelligence, blockchain technology, and data analytics, Kingxomiz aims to help businesses achieve scalability, streamline their operations, and ultimately create long-term value.

The Origins of Kingxomiz: A Visionary Beginning

The story of Kingxomiz begins with a visionary founder or group of entrepreneurs who recognized the need for a fresh, all-encompassing digital platform that could simplify complex digital business processes. Launched with the goal of bringing cutting-edge technologies to the forefront of various industries, Kingxomiz aimed to create a seamless integration of digital tools and services that could cater to the needs of diverse industries.

From its early days, Kingxomiz was built around a few core principles: innovation, scalability, and user-centric design. These principles helped the platform gain traction among forward-thinking businesses that wanted to stay ahead of the curve in a highly competitive and ever-evolving marketplace.

Key Factors Driving the Rise of Kingxomiz

1. Innovation at Its Core

One of the primary factors behind Kingxomiz’s rise is its unwavering commitment to innovation. The digital age is defined by rapid technological advancements, and Kingxomiz has consistently positioned itself as a company that not only keeps up with these changes but leads them. Whether through the use of AI and machine learning algorithms for predictive analytics, or blockchain technology for enhanced security and transparency, Kingxomiz continually explores and adopts new technologies to stay ahead of the competition.

This innovative approach has attracted businesses that are eager to adopt the latest tools to enhance their operations, improve customer engagement, and streamline their processes. With its robust technology stack, Kingxomiz provides solutions that are both forward-looking and practical, allowing its users to benefit from the best of what digital technology has to offer.

2. A Focus on User-Centric Solutions

At the heart of Kingxomiz’s growth is its commitment to providing user-centric solutions. The digital world is filled with tools, platforms, and technologies that promise great things, but few truly deliver a seamless experience for their users. Kingxomiz stands out by focusing on usability and ensuring that businesses can easily integrate its solutions into their existing operations.

Kingxomiz’s design philosophy revolves around simplicity, intuitiveness, and accessibility. This focus on user experience ensures that businesses can adopt the platform with minimal friction, reducing the barriers to entry that often deter organizations from embracing digital transformation. By simplifying complex systems, Kingxomiz empowers users to easily take advantage of its full range of features without needing specialized technical expertise.

3. Strategic Partnerships and Collaborations

As Kingxomiz continues to grow, one of its most strategic moves has been forming partnerships with key players in various industries. These collaborations have allowed the platform to expand its reach, access new markets, and strengthen its position in the digital ecosystem.

For example, by teaming up with industry-leading fintech companies, Kingxomiz has been able to offer its users a wider range of financial solutions that integrate seamlessly into its platform. Similarly, collaborations with e-commerce giants have allowed Kingxomiz to build a reputation as a go-to platform for businesses looking to enhance their online presence.

These strategic alliances have not only contributed to the company’s rapid rise but have also helped establish Kingxomiz as a trusted and reliable name in the digital world.

4. Data-Driven Decision Making

Kingxomiz has also capitalized on the growing importance of data in today’s digital age. Through its powerful data analytics capabilities, Kingxomiz provides businesses with valuable insights that enable them to make informed, data-driven decisions. Whether it’s optimizing marketing campaigns, analyzing customer behavior, or predicting market trends, Kingxomiz’s tools help businesses stay ahead of the curve.

The platform’s data-driven approach allows businesses to unlock new growth opportunities, mitigate risks, and improve their overall performance. By providing users with access to real-time analytics and predictive insights, Kingxomiz empowers businesses to make smarter, more effective decisions.

Kingxomiz’s Digital Empire: What Sets It Apart?

While Kingxomiz’s growth is impressive, what sets it apart from other digital platforms is its ability to create an ecosystem that supports not only its own growth but also the growth of its partners and users. Here are a few reasons why Kingxomiz is poised to establish itself as a dominant player in the digital space.

1. Versatility Across Industries

One of the key aspects of Kingxomiz’s success is its versatility. Unlike platforms that cater to a specific industry or niche, Kingxomiz is designed to serve a wide range of sectors, from e-commerce and fintech to healthcare, logistics, and entertainment. This broad applicability means that businesses in virtually any industry can benefit from the platform’s tools and solutions.

As more industries recognize the value of digital transformation, Kingxomiz is well-positioned to capitalize on this trend and expand its reach. The platform’s flexibility allows it to adapt to the unique needs of each industry, providing tailored solutions that drive growth and efficiency.

2. Seamless Integration with Existing Systems

Another standout feature of Kingxomiz is its ability to integrate seamlessly with existing business systems. Many businesses hesitate to adopt new technologies because of the complexity involved in integrating them into their current workflows. However, Kingxomiz makes the process of integration as smooth as possible, ensuring that businesses can adopt its solutions without disrupting their daily operations.

This seamless integration not only saves time and resources but also ensures that businesses can leverage Kingxomiz’s tools without having to completely overhaul their existing systems.

3. Cutting-Edge Security

As cyber threats continue to grow in complexity, security has become a major concern for businesses operating in the digital space. Kingxomiz addresses these concerns by implementing state-of-the-art security measures, ensuring that all data and transactions conducted on its platform are secure and protected.

Whether through encryption, multi-factor authentication, or blockchain technology, Kingxomiz is committed to providing a secure environment for businesses to operate in. This focus on security has earned the platform the trust of its users, making it a reliable and secure choice for businesses looking to embrace digital transformation.

The Future of Kingxomiz: A Digital Powerhouse

As Kingxomiz continues to expand its reach and grow its influence, the future looks incredibly bright for this emerging digital empire. The company’s relentless focus on innovation, user-centric solutions, strategic partnerships, and cutting-edge technology has positioned it as a leader in the digital space.

Looking ahead, Kingxomiz is poised to make even greater strides as it continues to push the boundaries of digital transformation. With a strong foundation and an eye on future growth, the rise of Kingxomiz as a digital powerhouse seems inevitable.

Conclusion: The Digital Empire Is Just Beginning

In conclusion, Kingxomiz: The Rise of a Digital Empire is a story of innovation, growth, and strategic foresight. By focusing on creating a versatile, user-friendly platform that addresses the needs of businesses across various industries, Kingxomiz is setting itself up to become a dominant force in the digital world. Its commitment to cutting-edge technology, seamless integration, and robust security makes it a reliable partner for businesses looking to succeed in an increasingly digital-driven world.

TECHNOLOGY

Unveiling Pernithia Galnith: A Unique Journey into Discovery

-

TECHNOLOGY3 months ago

TECHNOLOGY3 months agoWhat happened to spank bang

-

ENTERTAINMENT3 months ago

ENTERTAINMENT3 months agoWhat Is JerkMate? Exploring the Features and Purpose

-

FASHION3 months ago

FASHION3 months agoUnderstanding the Carmelita Neck: A Unique Fashion Detail

-

GENERAL3 months ago

GENERAL3 months agoUnveiling the 322 Messianic Prophecies: A Deep Dive

-

FASHION3 months ago

FASHION3 months agoDebonair blog:The Art of Stylish Living

-

BUSNIESS3 months ago

BUSNIESS3 months agoCrypto FintechZoom: Navigating the Future of Digital Finance

-

ENTERTAINMENT3 months ago

ENTERTAINMENT3 months agoDrake Exposed: The Untold Truth Behind the Music and Fame

-

ENTERTAINMENT3 months ago

ENTERTAINMENT3 months agoWhat Does It Mean to Be a Scratch Golfer?