TECHNOLOGY

What Are Sky Rockets Made Of: Key Components Explained

Published

1 month agoon

What Are Sky Rockets Made Of: Key Components Explained

Sky rockets are an integral part of fireworks displays, celebrations, and even space exploration in certain contexts. When you watch a skyrocket soar into the sky, you might marvel at the beautiful colors and mesmerizing effects, but have you ever wondered what exactly goes into making these rockets? In this article, we’ll explore the key components that make up a skyrocket, breaking down the different materials and parts that work together to create a stunning visual spectacle.

Understanding the Basics of Sky Rockets

Before diving into the individual components, it’s important to understand the basic concept of a skyrocket. A skyrocket is a type of firework designed to be launched into the sky, where it explodes or creates a visual effect. The design is a carefully balanced combination of propellants, fuses, and shells to ensure the rocket travels high into the air before it explodes or releases its visual effect.

Sky rockets are typically made up of several key parts that function together to ensure a controlled flight and a visually stunning display. These components are carefully crafted to provide the necessary propulsion, ignition, and control mechanisms to launch the rocket, while also determining the timing, speed, and impact of the firework.

Let’s break down the essential elements of a skyrocket.

1. The Rocket Shell

The rocket shell is the outer casing that houses the components of the skyrocket. This shell is usually made from a strong yet lightweight material like cardboard or plastic to withstand the forces exerted during the launch and explosion. The shell serves as a container for the rocket’s payload, which typically consists of the pyrotechnic compositions responsible for creating the visual effects.

The shape and size of the rocket shell can vary depending on the type of firework being created, with some shells designed to create a single large explosion and others crafted for more intricate effects such as multi-stage displays. The shell must be carefully constructed to allow the firework to safely ascend to its intended height before the ignition occurs.

Materials Used for Rocket Shells

- Cardboard: The most common material used for rocket shells due to its lightness and flexibility. Cardboard shells are inexpensive and strong enough to withstand the forces generated during the rocket’s flight.

- Plastic: Sometimes used in higher-end rockets, plastic shells are more durable and can be molded into specific shapes that affect the trajectory and effect of the rocket.

- Paper: For smaller and less advanced sky rockets, paper may be used to create the outer shell. Paper shells are lighter but can also be more fragile, making them suitable for less powerful displays.

2. Propellant

The propellant is the substance responsible for providing the thrust that propels the skyrocket into the air. Propellants are composed of a mixture of chemicals that produce gases when ignited, forcing the rocket to ascend. These chemical mixtures are carefully formulated to create the optimal thrust for the rocket to reach its desired altitude.

The propellant must be carefully balanced for the rocket to travel at the right speed and achieve the necessary height. If the propellant is too weak, the rocket may not reach a high enough altitude. On the other hand, if it’s too powerful, the rocket could explode prematurely or veer off course.

Common Propellant Ingredients

- Potassium Nitrate (KNO₃): This compound is commonly used in solid rocket propellants because it provides the necessary oxygen for combustion.

- Charcoal: Used as a fuel in many rocket propellant mixtures, charcoal is highly combustible and provides the energy needed for the rocket’s flight.

- Sulfur: Another common fuel source that helps the propellant burn at a steady rate.

- Aluminum Powder: Often added to the propellant to enhance the brightness of the rocket’s effects during the flight or explosion.

3. The Fuse

The fuse in a skyrocket plays a crucial role in determining the timing of the explosion or visual effect. A fuse is essentially a slow-burning material that ignites the rocket’s pyrotechnic compositions once the rocket has reached a certain altitude. Without a fuse, the rocket would explode prematurely, either while still on the ground or during the ascent.

Fuses can be made from various materials, including black powder or more modern chemical compositions. The fuse must be carefully timed to ensure that it ignites the rocket’s payload at the correct moment, resulting in the desired effect, whether it’s a burst of color, a shower of sparks, or an explosion.

Types of Fuses Used

- Visco Fuse: The most common type of fuse, this is a slow-burning material that is typically made from a combination of saltpeter and other chemicals. It burns at a steady rate, allowing for precise timing in pyrotechnic displays.

- Electric Fuse: In some cases, electric fuses are used in more advanced fireworks to trigger the ignition of the rocket’s payload at a specific moment, often controlled remotely.

4. Pyrotechnic Composition

The pyrotechnic composition is the heart of the skyrocket. These chemical mixtures are responsible for the visual effects that are created when the rocket explodes or bursts into the air. Pyrotechnic compositions are carefully mixed to produce various colors, effects, and sparks that are characteristic of fireworks displays.

These compositions are typically placed inside the rocket shell in small containers or compartments. The composition ignites when the fuse reaches it, creating the desired effect, whether it’s a burst of color, a shower of sparks, or a strobe-like effect.

Common Pyrotechnic Ingredients

- Strontium Carbonate: Creates red-colored flames when ignited, often used for creating the classic red hues in fireworks.

- Copper Compounds: Produces blue or green colors when burned, adding to the range of hues that sky rockets can display.

- Barium Compounds: Used for green or white colors, barium is another common pyrotechnic ingredient.

- Magnesium and Aluminum: These metals create bright white flashes and intense sparks, often seen in the finale of many fireworks displays.

- Titanium: When ignited, titanium produces bright, sparkling effects that add to the dramatic nature of the skyrocket’s display.

5. The Rocket’s Nozzle

The nozzle is an essential part of the rocket’s propulsion system. It is located at the bottom of the rocket and helps direct the force of the propellant to ensure that the rocket flies in the intended direction. The nozzle is designed to provide thrust in a controlled and focused manner, ensuring that the rocket flies in a straight line, ascends at the correct angle, and ultimately reaches its target altitude.

The nozzle’s design is crucial to the success of the launch. A poorly constructed or poorly aligned nozzle can cause the rocket to veer off course or even cause the rocket to fail to launch entirely.

Materials for the Nozzle

- Metal: Often, nozzles are made of heat-resistant metal to withstand the intense heat generated during ignition.

- Ceramic: For high-performance rockets, ceramic nozzles may be used to provide even greater durability against high temperatures.

6. Stabilizing Fins

While not present in every skyrocket design, stabilizing fins are sometimes used to help control the flight path of the rocket. These fins help keep the rocket stable as it ascends and ensure that it flies straight, preventing it from spinning out of control or veering off course. The fins are typically small and attached to the bottom of the rocket.

Materials Used for Fins

- Plastic: Lightweight and flexible, plastic is commonly used for the fins in consumer-grade rockets.

- Cardboard: In some cases, cardboard is used for the fins due to its lightweight nature and easy malleability.

Conclusion

Sky rockets are an intricate combination of various materials and components, all working together to produce a thrilling visual display. From the propellant that provides thrust to the pyrotechnic compositions that create color and light, each component plays a crucial role in ensuring that the rocket performs as intended. Understanding the key parts that go into a skyrocket—such as the rocket shell, propellant, fuse, pyrotechnic compositions, nozzle, and stabilizing fins—gives us a deeper appreciation for the science and artistry behind these amazing fireworks displays.

As technology advances, we can expect more sophisticated and creative designs to emerge, further enhancing the beauty and complexity of sky rockets for future celebrations and events.

You may like

TECHNOLOGY

Exploring Top Name Brand of Headers: A Comprehensive Guide

Published

6 days agoon

March 25, 2025

Exploring Top Name Brand of Headers: A Comprehensive Guide

What name brand of headers are? When it comes to improving the performance of your vehicle, one of the most significant upgrades you can make is installing a high-quality set of headers. Headers are a crucial component of an engine’s exhaust system that help improve airflow, boost horsepower, and enhance engine efficiency. However, with so many brands on the market, it can be overwhelming to choose the best set of headers for your vehicle. In this comprehensive guide, we will explore some of the top name brands of headers, the features that make them stand out, and what you need to consider before making a purchase.

What Are Headers and Why Are They Important?

Before diving into the top brands, it’s important to understand what headers are and how they impact your vehicle’s performance.

Headers are a part of the exhaust system that replace the stock exhaust manifolds. They serve to channel exhaust gases away from the engine more efficiently, reducing restrictions and improving the overall flow of gases out of the engine. The result is better engine performance, increased horsepower, improved fuel efficiency, and a more aggressive exhaust sound.

In short, headers optimize the engine’s ability to breathe, which directly impacts acceleration, throttle response, and overall engine performance. Upgrading to aftermarket headers can make a noticeable difference in how your vehicle drives.

Factors to Consider When Choosing Headers

When selecting headers for your vehicle, several factors come into play, including material, design, and compatibility with your engine. What name brand of headers are? Here are some important things to keep in mind when choosing headers:

-

Material: Headers are typically made from materials like stainless steel, mild steel, or ceramic-coated steel. Stainless steel headers are known for their durability and resistance to corrosion, while ceramic-coated headers offer better heat resistance and performance benefits.

-

Design: There are two main types of header designs: long tube and short tube headers. Long tube headers provide better performance at higher RPMs, while short tube headers offer better torque at lower RPMs.

-

Compatibility: Not all headers are compatible with every vehicle. It’s important to choose a set that matches your car’s make, model, and engine size.

-

Finish: The finish of the headers can affect both their performance and aesthetics. Ceramic coatings, for example, help to reduce heat buildup, while polished stainless steel provides a sleek appearance.

-

Budget: While investing in high-quality headers can improve your vehicle’s performance, it’s important to stay within your budget. Prices can vary depending on the brand and material, so it’s essential to find a balance between quality and cost.

Top Name Brands of Headers

Now that we’ve covered the basics, let’s dive into the top name brands of headers that are widely recognized for their quality, performance, and reliability.

1. BBK Performance

BBK Performance is a well-known brand in the aftermarket performance industry. Known for producing high-quality headers, BBK’s products are designed for both street and racing applications. The company offers a wide range of headers, including long tube, short tube, and shorty headers, which are engineered to maximize horsepower and torque.

Key Features:

-

CNC mandrel-bent tubing for maximum exhaust flow

-

High-quality materials such as stainless steel and ceramic coatings

-

Designed for easy installation with factory-like fitment

BBK headers are popular for their outstanding performance gains and are often chosen by enthusiasts looking to enhance their vehicle’s power output.

2. Flowmaster

Flowmaster is one of the most recognized names in the performance exhaust world, known primarily for their exhaust systems. However, Flowmaster also manufactures a variety of high-performance headers that are engineered to complement their exhaust systems.

Key Features:

-

Utilizes high-grade stainless steel for durability

-

Enhanced exhaust flow to reduce backpressure

-

Focus on improved throttle response and performance at higher RPMs

Flowmaster headers are designed to deliver a deep, aggressive exhaust tone while improving horsepower and torque, making them an excellent choice for those looking for performance and sound.

3. Kooks Headers & Exhaust

Kooks Headers & Exhaust is a premium brand specializing in custom-built performance exhaust systems and headers. Known for their high-quality craftsmanship and performance-oriented products, Kooks is a favorite among car enthusiasts and professional racers alike.

Key Features:

-

Full custom fabrication options for unique vehicles

-

Stainless steel and ceramic-coated headers for durability and heat resistance

-

Increased horsepower and torque, particularly at high RPMs

Kooks headers are typically more expensive than other brands, but they are highly regarded for their performance gains and exceptional build quality.

4. Hedman Hedders

Hedman Hedders is another reputable brand known for producing high-performance headers. With over 60 years in the industry, Hedman has built a solid reputation for providing reliable and affordable headers. Their product range includes headers for street performance, racing, and off-road applications.

Key Features:

-

Long tube and short tube header options

-

Built with heavy-duty steel and available in ceramic-coated or painted finishes

-

Engineered for maximum exhaust flow and durability

Hedman Hedders offers great value for money, making them a top choice for both budget-conscious consumers and those looking for performance upgrades.

5. Speed Engineering

Speed Engineering is a newer player in the performance parts market, but they’ve quickly gained popularity thanks to their budget-friendly yet high-performance headers. What name brand of headers are? Their products are designed to provide improved airflow, horsepower, and torque, making them a great option for those looking to get the most out of their engine without breaking the bank.

Key Features:

-

Affordable pricing without sacrificing performance

-

Available in both mild steel and stainless steel options

-

Long tube and short tube header designs

Speed Engineering headers are especially popular among muscle car owners and racing enthusiasts who want to enhance their vehicle’s performance without spending too much.

6. American Racing Headers

American Racing Headers is known for providing high-quality, custom-made headers for various performance applications. Their headers are designed to improve exhaust flow and engine performance while providing a durable and long-lasting product.

Key Features:

-

Fully customizable header options for different makes and models

-

Premium-grade stainless steel construction

-

Excellent attention to detail in manufacturing and fitment

American Racing Headers are a popular choice for high-end performance builds, especially for cars used in motorsports.

7. JBA Performance Exhaust

JBA Performance Exhaust has been a trusted name in the aftermarket performance parts industry for decades. Their headers are known for their quality, easy installation, and performance gains, making them an excellent choice for both casual car enthusiasts and racers.

Key Features:

-

50-state legal headers (CARB-compliant in certain states)

-

Mandrel-bent tubing for optimized exhaust flow

-

Available in both short tube and long tube designs

JBA headers are engineered to deliver increased horsepower and torque while maintaining emissions compliance, making them an ideal option for street-driven vehicles.

Conclusion

Upgrading your vehicle with a set of high-performance headers is an effective way to boost horsepower, enhance engine efficiency, and improve overall driving experience. What name brand of headers are? With so many brands on the market, it’s essential to consider factors such as material, design, and fitment before making a purchase.

Top brands like BBK Performance, Flowmaster, Kooks Headers & Exhaust, Hedman Hedders, Speed Engineering, American Racing Headers, and JBA Performance Exhaust are all known for delivering excellent performance, durability, and value for money. By understanding the different options available and choosing the right set of headers for your needs, you can enjoy the benefits of improved engine performance and a more thrilling driving experience.

When shopping for headers, always ensure that you are purchasing from a reputable brand to guarantee you are getting the best product for your vehicle’s needs. Whether you’re a street driver or a racer, a high-quality set of headers will elevate your vehicle’s performance and sound, making every drive more enjoyable.

TECHNOLOGY

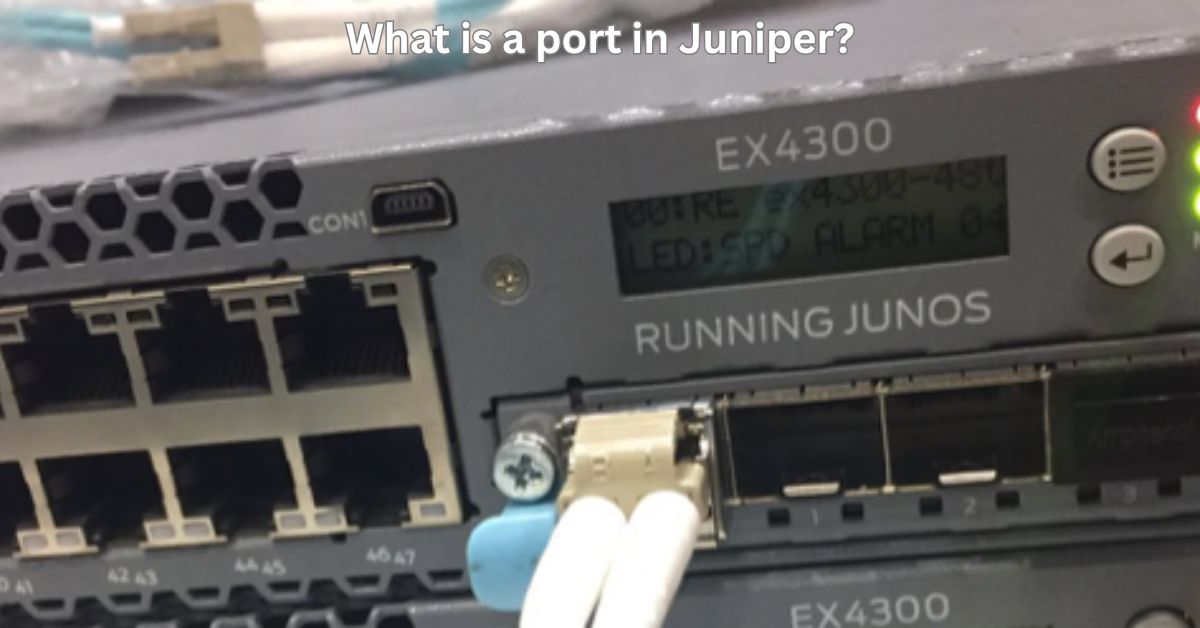

Understanding Port in Juniper: A Key to Network Connectivity

Published

1 week agoon

March 24, 2025

Understanding Port in Juniper: A Key to Network Connectivity

What is a port in Juniper? When it comes to networking, the term “port” holds a significant meaning, especially in the context of devices and networking equipment. For anyone working with Juniper Networks, understanding how ports work is crucial for effective configuration and maintenance. Juniper Networks, known for its high-performance networking devices and software, uses ports to enable communication between different devices across a network. In this article, we will dive into the concept of ports in Juniper devices, their types, and their role in network connectivity.

What are Ports in Networking?

Before delving into Juniper’s specific implementation of ports, it’s important to understand what a network port is. In basic terms, a network port is an interface through which data can flow between network devices. It acts as a communication channel that allows devices to transmit and receive information.

In the context of physical networking devices, such as routers or switches, ports usually refer to the hardware interfaces where cables are plugged in. These physical ports could be Ethernet ports, fiber ports, or other types of media. For virtual devices, ports refer to logical interfaces, such as VLANs or subinterfaces, that help manage network traffic in a more granular manner.

The Importance of Ports in Network Connectivity

Ports play a vital role in network connectivity by enabling devices to connect and exchange data. Without these ports, devices wouldn’t be able to send or receive information. Whether it’s a router connecting multiple networks or a switch forwarding traffic between devices within the same network, ports are fundamental components in the data transfer process.

For Juniper devices, ports allow various network functions like routing, switching, and bridging to happen efficiently. The configuration and management of these ports determine how well data can flow between devices, impacting the overall network performance.

Types of Ports in Juniper Networks

Juniper Networks offers various types of ports designed to support different network environments. These ports are categorized based on their function, usage, and physical or logical nature.

1. Physical Ports

Physical ports are the most common types of ports found on Juniper devices like routers, switches, and firewalls. These ports represent the hardware interfaces where physical cables, such as Ethernet, fiber, or copper, can be connected.

-

Ethernet Ports: These are the most common type of ports found in Juniper devices. They come in different speeds, such as 1GbE (Gigabit Ethernet), 10GbE (10 Gigabit Ethernet), and even 40GbE or 100GbE in high-performance models. Ethernet ports allow devices to communicate using the Ethernet protocol over copper or fiber cables.

-

Fiber Ports: Fiber ports are designed for high-speed, long-distance communication. They use fiber optic cables, which provide faster data transmission rates compared to copper cables. Juniper devices with fiber ports can connect to other fiber-enabled devices for high-throughput data transfer.

-

Gigabit and 10-Gigabit Ports: These ports offer high-speed connections and are used primarily in environments requiring significant bandwidth, such as data centers and large enterprise networks.

2. Logical Ports

In addition to physical ports, Juniper devices also use logical ports. These are virtualized interfaces created in software and are not tied to specific hardware connections. Logical ports allow for more flexible and scalable network configurations.

-

VLAN Interfaces: A VLAN (Virtual Local Area Network) interface is a logical port that allows network segmentation within the same physical network. By assigning different devices to different VLANs, network administrators can improve security and traffic management.

-

Subinterfaces: Subinterfaces are logical divisions of a physical interface, often used to create multiple IP addresses on a single physical interface. These are particularly useful when multiple networks need to be connected through a single router interface.

-

Loopback Interfaces: A loopback interface is a virtual interface that can be used for testing and troubleshooting. It does not rely on physical hardware and provides a stable, always-up connection point on the device.

3. Management Ports

Juniper devices come with dedicated management ports, such as the Console Port and Auxiliary Port, which are used for device management and configuration.

-

Console Port: The console port allows administrators to directly connect to the device for configuration and troubleshooting. This is a serial port that provides direct access to the system, bypassing network issues.

-

Auxiliary Port: The auxiliary port is used for remote management and sometimes for backup configurations. It works similarly to the console port but may be used for network-based administration.

4. Specialized Ports

Some Juniper devices offer specialized ports for specific use cases, like SFP+ (Small Form-factor Pluggable) ports, which are used for high-speed fiber-optic connections. What is a port in Juniper? What is a port in Juniper? These specialized ports allow for more flexibility, as different types of modules can be inserted depending on the network’s needs.

How Ports in Juniper Affect Network Performance

The ports in Juniper devices play a significant role in determining the overall performance of the network. Their speed, configuration, and usage can impact factors such as:

-

Bandwidth: The type of port determines the maximum bandwidth available for data transfer. High-speed ports, such as 10GbE or 100GbE, are essential for networks that handle large volumes of data.

-

Latency: Physical and logical ports must be optimized to ensure minimal latency in data transmission. Poorly configured or underperforming ports can increase network delays.

-

Redundancy and Reliability: Using multiple ports for redundancy, such as link aggregation or using multiple physical interfaces for a connection, ensures that network traffic can still flow smoothly in case of a failure in one port.

-

Security: Ports also play a role in network security. Through proper port configuration, such as using VLANs or segmenting traffic, administrators can control and limit access to sensitive parts of the network.

Configuring Ports in Juniper Devices

Configuring ports in Juniper devices is typically done through the Junos OS, which is the operating system used in most Juniper hardware. The Junos OS provides a rich set of features to configure and manage ports effectively.

Basic Configuration Steps

-

Assigning IP Addresses: For Ethernet and VLAN ports, the first step is assigning IP addresses to the interfaces. This allows the device to communicate with other devices on the network.

-

Configuring VLANs: If the device is part of a larger network, VLANs must be configured to segregate traffic. This is done by creating logical interfaces and assigning them to specific VLAN IDs.

-

Enabling Ports: In some cases, ports might be administratively disabled, meaning they cannot carry traffic. To enable them, a simple command is issued to activate the port.

-

Link Aggregation: For higher bandwidth needs, administrators might configure link aggregation on multiple ports to combine their bandwidth into a single logical connection.

Troubleshooting Port Issues

Issues related to ports can cause network outages or degraded performance. Some common issues include:

-

Port Flapping: This occurs when a port continuously goes up and down, which could be due to faulty cables or hardware. Troubleshooting involves checking physical connections and reviewing configuration logs.

-

Configuration Errors: Misconfigured ports can prevent data from flowing correctly. Ensuring proper settings, such as VLAN tagging or IP addressing, is crucial.

-

Speed and Duplex Mismatches: When the speed and duplex settings between two connected devices are mismatched, communication can fail. Ensuring both ends of the connection are configured with the same speed and duplex settings is essential.

Conclusion

Ports are fundamental to the operation of Juniper Networks’ devices. Whether you’re working with physical Ethernet ports or virtual VLAN interfaces, understanding the role of ports is key to ensuring optimal network performance. What is a port in Juniper? Properly configuring, managing, and troubleshooting ports helps network administrators maintain a stable and efficient network environment.

By leveraging the power of Juniper’s network ports, organizations can ensure fast, reliable, and secure connectivity across their entire network infrastructure, driving business success and improved communication.

Laser Robot: What Are They and How Do They Work?

What is Laser Robot? Laser robots are transforming industries by combining the precision of lasers with the adaptability and efficiency of robotic systems. These advanced machines are used in a wide range of applications, from manufacturing and medical procedures to research and defense. By integrating lasers and robotics, they provide increased precision, automation, and safety, offering solutions that traditional methods can’t always match. This article will dive into what laser robots are, how they work, their uses, and the future of this cutting-edge technology.

What Are Laser Robots?

Laser robots are robotic systems equipped with laser technology that allows them to perform tasks with extreme accuracy and efficiency. The laser component can be used for various functions such as cutting, engraving, welding, measuring, and even medical treatments. These robots combine the mobility and versatility of robotic arms with the power and precision of lasers to perform operations that require a high degree of precision, speed, and automation.

These robots are programmed to perform tasks with minimal human intervention, making them ideal for repetitive tasks in manufacturing, medical procedures, and other high-precision fields. Whether it’s cutting materials in an industrial setting or performing delicate surgeries, laser robots offer a range of benefits that set them apart from traditional machines and tools.

How Do Laser Robots Work?

Laser robots combine the fundamentals of robotics with advanced laser technology. Here’s a breakdown of how they work:

1. The Robotic Arm: Mobility and Precision

Most laser robots feature a robotic arm that allows the machine to move and manipulate objects or tools with high precision. The robotic arm is typically controlled by a computer system, which uses pre-programmed instructions or real-time data from sensors to control the arm’s movement.

The arm is capable of executing a variety of tasks such as moving laser equipment, positioning materials, or interacting with the environment. The arm’s high degree of flexibility enables it to perform intricate tasks that would otherwise be challenging for traditional machinery or manual labor.

2. Laser Technology: Power and Precision

The laser in a laser robot is the heart of the system, providing the necessary power for precision tasks. Lasers operate by emitting focused light beams that can be directed to specific spots on materials or objects. The most common types of lasers used in laser robots are CO2 lasers, fiber lasers, and diode lasers.

-

CO2 Lasers: These are widely used in cutting and engraving applications due to their ability to cut through materials such as metal, wood, and plastics with great precision.

-

Fiber Lasers: Known for their efficiency and ability to cut through harder materials, fiber lasers are often used in high-precision applications like welding and marking.

-

Diode Lasers: These are typically used for more specific applications, such as medical procedures, where precision and minimal heat generation are crucial.

The laser system is integrated with the robotic arm, allowing the robot to move the laser precisely to perform its tasks. The laser can be controlled to vary in power, focus, and duration, making it adaptable to different tasks.

3. Sensors and Feedback Mechanisms: Ensuring Accuracy

What is Laser Robot? Laser robots are equipped with sensors that allow them to perceive and interact with their environment. These sensors can include cameras, LIDAR (Light Detection and Ranging), infrared sensors, and pressure sensors, among others.

Sensors provide real-time data about the position, shape, and size of objects in the robot’s environment. This feedback helps the robotic system adjust its movements and the laser’s intensity to ensure accuracy. For example, if a laser robot is cutting a piece of metal, the sensors will provide continuous feedback about the material’s thickness and position, allowing the robot to adjust the laser’s power accordingly.

The integration of sensors allows laser robots to perform tasks with a high degree of automation, reducing the need for human intervention and ensuring consistent results.

Applications of Laser Robots

Laser robots are versatile machines that find applications across various industries. Here are some of the key sectors where laser robots are making an impact:

1. Manufacturing and Industrial Automation

In manufacturing, laser robots are used for tasks such as cutting, welding, engraving, and marking materials. The precision and speed of laser robots allow manufacturers to automate processes that were traditionally done by human workers or with slower, less efficient machinery.

For example:

- Laser Cutting: Laser robots can cut through metals, plastics, and other materials with exceptional precision, making them ideal for industries like automotive manufacturing, aerospace, and electronics.

- Laser Welding: Laser robots can be used for high-precision welding, providing stronger, more consistent welds than traditional methods.

- Laser Engraving and Marking: Laser robots can engrave or mark surfaces with intricate designs, serial numbers, or logos. This is useful in industries such as electronics, packaging, and jewelry manufacturing.

The integration of laser robots into these industries helps reduce production costs, increase efficiency, and improve the quality of finished products.

2. Medical Applications

In the medical field, laser robots are used for a variety of applications, including surgery, diagnostics, and treatment. These robots provide greater precision than manual methods, leading to better patient outcomes.

For example:

- Laser Surgery: Laser robots are used in delicate surgeries such as eye surgery (e.g., LASIK), where precision is crucial. The robots can perform precise cuts or remove tissue without damaging surrounding areas, leading to faster recovery times.

- Medical Imaging: Laser robots are also used in medical imaging techniques such as laser scanning, which can be used to detect tumors or other abnormalities inside the body.

- Biopsy and Treatment: Laser robots can perform minimally invasive procedures like biopsies or targeted treatment for conditions such as cancer.

The main advantage of laser robots in the medical field is their ability to perform intricate procedures with minimal invasion, reducing the risk of complications and improving patient recovery times.

3. Research and Development

Laser robots are used extensively in research, particularly in fields that require precise measurements, testing, and data collection. For example:

- Material Testing: Laser robots are used to test the properties of materials by exposing them to controlled laser beams and analyzing how they respond.

- Particle Accelerators: Laser robots are also employed in particle accelerators, where lasers are used to create beams of charged particles for research in physics and material science.

In R&D, the precision and repeatability of laser robots make them indispensable tools for experiments and innovations across various scientific fields.

4. Defense and Military

In defense and military applications, laser robots are used for tasks ranging from surveillance and reconnaissance to targeting and weaponry. They are employed to provide high accuracy in challenging environments, such as combat zones or disaster areas. For example:

- Drones with Laser Weapons: Laser robots are sometimes mounted on drones, offering precise targeting capabilities for neutralizing threats.

- Surveillance: Laser robots are also used for surveillance, offering the ability to scan large areas with laser beams for detecting obstacles, mapping terrain, and identifying potential threats.

The ability to deploy laser robots in high-risk environments with minimal human involvement is crucial in defense applications.

Benefits of Laser Robots

Laser robots offer numerous benefits across various industries.What is Laser Robot? Here are a few reasons why these advanced machines are becoming increasingly popular:

1. Increased Precision

The combination of robotics and lasers provides a level of precision that human operators or traditional machines cannot achieve. The lasers allow for extremely fine control over cutting, welding, engraving, and other operations, ensuring that every task is completed with the highest level of accuracy.

2. Automation and Efficiency

Laser robots automate complex tasks, allowing for faster production times, reduced human error, and more consistent results. This leads to greater efficiency in manufacturing, medical procedures, and other sectors.

3. Safety

Laser robots can perform dangerous tasks in hazardous environments, such as cutting through toxic materials, welding in high-temperature conditions, or conducting military operations. This reduces the risk to human workers and minimizes accidents.

4. Flexibility

The versatility of laser robots allows them to be used in a wide variety of applications, from industrial manufacturing to medical surgeries. Their ability to adapt to different tasks makes them valuable assets across multiple industries.

The Future of Laser Robots

As technology continues to advance, laser robots will become even more sophisticated. Future developments may include enhanced AI capabilities for smarter decision-making, improvements in laser technology for even higher precision, and greater integration with other automated systems. These advancements will continue to open up new possibilities for laser robots, especially in fields like manufacturing, healthcare, and research.

Conclusion

Laser robots represent the future of precision automation, combining the power of lasers with the flexibility of robotic systems to revolutionize industries across the board. From manufacturing to healthcare and defense, these advanced machines are capable of performing tasks with unprecedented accuracy, speed, and efficiency. As technology continues to evolve, the role of laser robots will only grow, offering even greater capabilities and applications that will shape the future of many sectors.

Trending

-

TECHNOLOGY2 months ago

TECHNOLOGY2 months agoWhat happened to spank bang

-

ENTERTAINMENT2 months ago

ENTERTAINMENT2 months agoWhat Is JerkMate? Exploring the Features and Purpose

-

BUSNIESS2 months ago

BUSNIESS2 months agoCrypto FintechZoom: Navigating the Future of Digital Finance

-

FASHION2 months ago

FASHION2 months agoDebonair blog:The Art of Stylish Living

-

TECHNOLOGY1 month ago

TECHNOLOGY1 month agoWhat Guns Use .335 Ammo?

-

GENERAL2 months ago

GENERAL2 months agoUnveiling the 322 Messianic Prophecies: A Deep Dive

-

ENTERTAINMENT2 months ago

ENTERTAINMENT2 months agoWhat Does It Mean to Be a Scratch Golfer?

-

BUSNIESS2 months ago

BUSNIESS2 months agoTNA Board: Shaping the Future of Innovation and Leadership